Recovery/recycling/recharging equipment certified to sae j2788 – SAE J2788-certified recovery, recycling, and recharging equipment play a crucial role in ensuring the safety, efficiency, and environmental sustainability of various industrial operations. This article provides an in-depth overview of the purpose, benefits, applications, design, maintenance, safety considerations, emerging trends, and industry standards related to SAE J2788-certified equipment, offering valuable insights for professionals involved in these operations.

Certified equipment meets stringent requirements and standards, ensuring optimal performance and compliance with regulatory guidelines. It offers numerous advantages, including enhanced safety measures, improved operational efficiency, and reduced environmental impact. Understanding the key aspects of SAE J2788-certified equipment empowers businesses to make informed decisions, optimize their operations, and contribute to a more sustainable future.

Certified Equipment Overview

SAE J2788 certification is a globally recognized standard for recovery, recycling, and recharging equipment used in the automotive industry. Certified equipment ensures compliance with safety, environmental, and performance requirements, providing numerous benefits for users.

Key Requirements and Standards, Recovery/recycling/recharging equipment certified to sae j2788

- Containment and leak prevention measures

- Efficient refrigerant recovery and recycling

- Accurate pressure and temperature monitoring

- Compliance with environmental regulations

- Operator safety features

Types of Certified Equipment

- Recovery machines

- Recycling machines

- Recharge stations

- Leak detectors

- Pressure testing equipment

Benefits of Using Certified Equipment

Safety and Compliance

- Minimizes refrigerant leaks and exposure

- Ensures compliance with environmental regulations

- Reduces the risk of accidents and injuries

Efficiency and Productivity

- Faster and more efficient recovery and recycling

- Improved accuracy and precision in recharging

- Reduces downtime and maintenance costs

Environmental Protection

- Prevents refrigerant emissions into the atmosphere

- Promotes sustainable refrigerant management practices

- Contributes to the reduction of greenhouse gas emissions

Industry Applications and Use Cases

Automotive Repair and Maintenance

- Recovery and recycling of refrigerants during AC system repairs

- Recharging of AC systems with fresh or recycled refrigerant

- Leak detection and pressure testing

Refrigerant Manufacturing and Distribution

- Purification and recycling of refrigerant gases

- Filling and packaging of refrigerant containers

- Quality control and testing of refrigerants

HVAC and Refrigeration Systems

- Recovery and recycling of refrigerants from commercial and industrial systems

- Recharging of refrigeration and AC units

- Maintenance and repair of HVAC and refrigeration systems

Equipment Design and Specifications

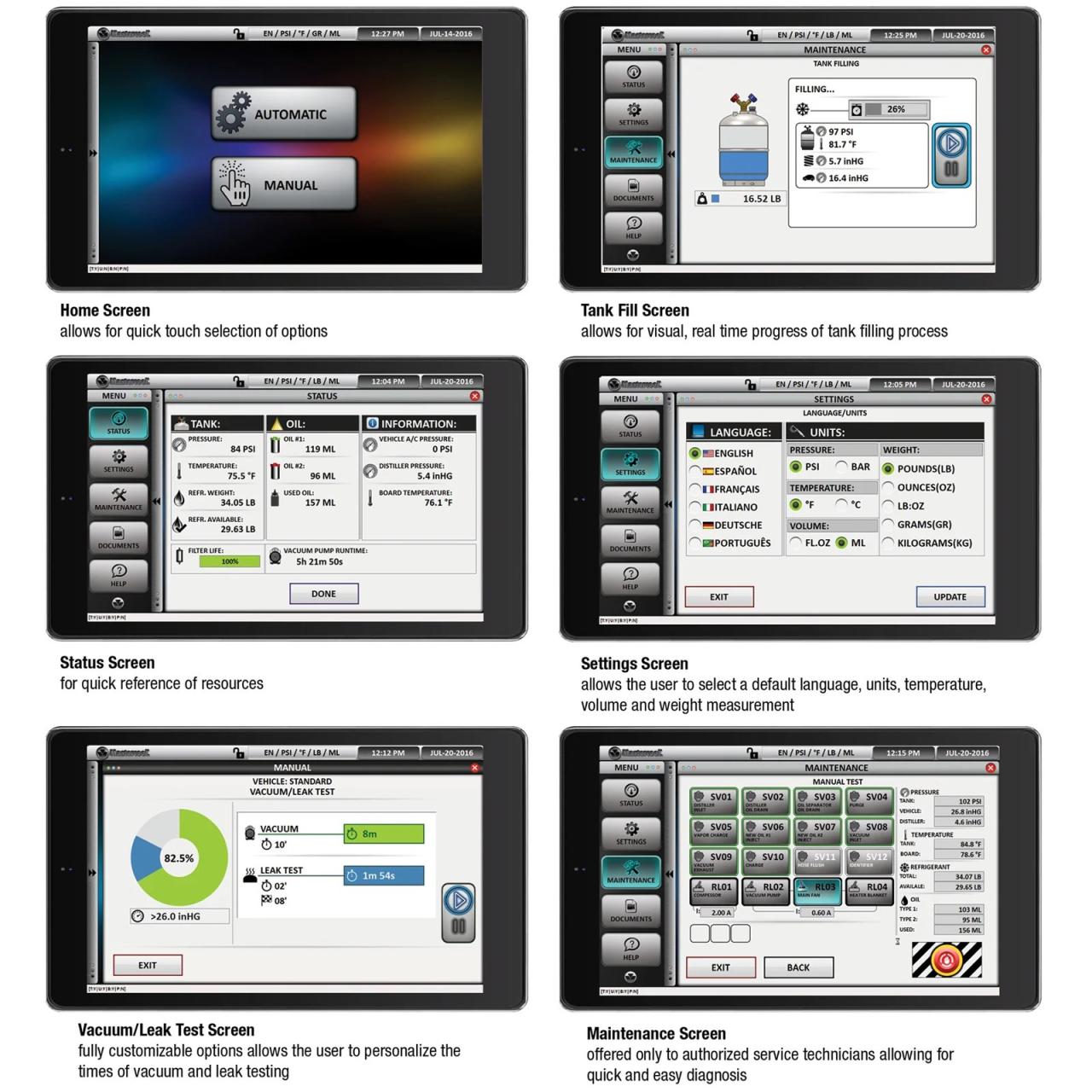

Key Design Features

- Durable construction and materials

- Ergonomic design for ease of use

- Integrated safety features

- Advanced control systems

- Digital displays and user interfaces

Components and Systems

- Recovery and recycling compressors

- Refrigerant condensers and evaporators

- Pressure gauges and temperature sensors

- Filtration and purification systems

- Electronic control modules

Comparative Analysis

| Feature | Equipment A | Equipment B |

|---|---|---|

| Recovery Rate | 95% | 98% |

| Pressure Range | 0-500 psi | 0-750 psi |

| Refrigerant Capacity | 50 lbs | 75 lbs |

Maintenance and Best Practices: Recovery/recycling/recharging Equipment Certified To Sae J2788

Recommended Procedures

- Regular inspections and calibration

- Preventive maintenance and repairs

- Use of genuine parts and accessories

- Training and certification of operators

- Proper handling and storage of refrigerants

Maintenance Schedule

- Daily: Check fluid levels and leaks

- Weekly: Calibrate pressure gauges

- Monthly: Inspect hoses and connections

- Annually: Comprehensive inspection and service

Safety Considerations

Potential Hazards

- Refrigerant leaks and exposure

- Electrical hazards

- High-pressure systems

- Fire and explosion risks

Safety Precautions

- Wear appropriate personal protective equipment

- Follow manufacturer’s instructions and safety guidelines

- Use certified equipment and trained personnel

- Ventilate work areas and avoid confined spaces

- Have an emergency plan in place

Emerging Trends and Advancements

New Technologies

- Digital refrigerant identification systems

- Automatic refrigerant recovery and recycling

- Cloud-based data monitoring and diagnostics

Industry Innovations

- Improved energy efficiency and refrigerant recovery rates

- Development of low-GWP and natural refrigerants

- Increased focus on sustainability and environmental compliance

Industry Standards and Regulations

Regulatory Bodies

- Environmental Protection Agency (EPA)

- Society of Automotive Engineers (SAE)

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

Industry Standards

- SAE J2788: Standard for Recovery, Recycling, and Recharging Equipment

- EPA Section 608: Refrigerant Management Regulations

- ASHRAE Standard 15: Safety Standard for Refrigeration Systems

Comparative Analysis

| Requirement | SAE J2788 | EPA Section 608 |

|---|---|---|

| Equipment Certification | Mandatory | Required for specific refrigerants |

| Refrigerant Recovery Rate | Minimum 95% | Minimum 80% |

| Leak Detection Sensitivity | 1/2 ounce per year | 1 ounce per year |

FAQ Resource

What are the key benefits of using SAE J2788-certified equipment?

SAE J2788-certified equipment offers numerous benefits, including enhanced safety measures, improved operational efficiency, reduced environmental impact, and compliance with industry standards and regulations.

How does SAE J2788 certification ensure safety in recovery, recycling, and recharging operations?

SAE J2788 certification mandates the incorporation of specific safety features and protocols into certified equipment, minimizing potential hazards and ensuring the well-being of operators and the environment.

What are some emerging trends in SAE J2788-certified equipment?

Emerging trends include the integration of advanced technologies such as automation, remote monitoring, and data analytics, which enhance equipment performance, safety, and environmental sustainability.