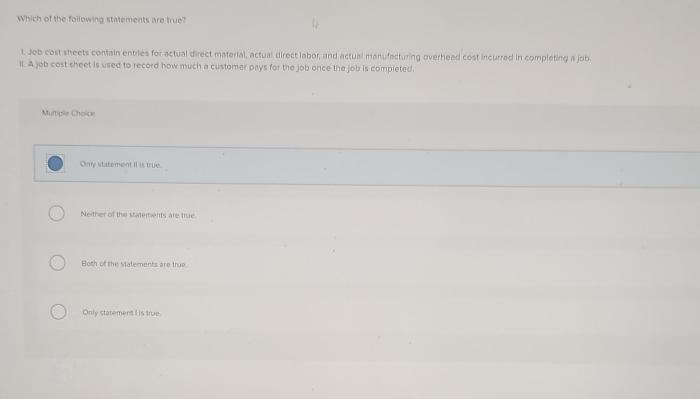

Job cost sheets contain entries for actual direct material – Job cost sheets play a crucial role in capturing actual direct material costs, providing valuable insights into the consumption and expenditure of materials used in specific projects or tasks. Understanding how these costs are recorded and tracked is essential for accurate job costing and effective project management.

Actual Direct Material Costs: Job Cost Sheets Contain Entries For Actual Direct Material

Actual direct material costs represent the actual cost of materials used in the production of goods or services. These costs include the purchase price of the materials, as well as any transportation or handling costs incurred in getting the materials to the production facility.

Examples of actual direct material costs include:

- Raw materials used in manufacturing

- Components used in assembling products

- Packaging materials used to ship products

Tracking actual direct material costs is important for several reasons:

- It helps businesses to accurately calculate the cost of goods sold.

- It allows businesses to identify areas where they can reduce material costs.

- It provides information that can be used to make informed decisions about pricing and production levels.

Job Cost Sheets and Actual Direct Material Costs, Job cost sheets contain entries for actual direct material

Actual direct material costs are recorded on job cost sheets. A job cost sheet is a document that tracks the costs associated with a specific job or project. The following table shows an example of a job cost sheet that includes entries for actual direct material costs:

| Job Number | Date | Description | Amount |

|---|---|---|---|

| 12345 | 2023-03-08 | Direct materials | $1,000 |

Methods for Tracking Actual Direct Material Costs

There are several different methods for tracking actual direct material costs. Some of the most common methods include:

- Material requisition system:This system requires employees to submit a requisition form for any materials they need. The requisition form is then approved by a supervisor, and the materials are issued to the employee.

- Inventory control system:This system tracks the inventory of materials on hand. When materials are issued to employees, the inventory control system is updated to reflect the change in inventory.

- Barcode scanning system:This system uses barcode scanners to track the movement of materials. When materials are issued to employees, the barcode scanner is used to scan the barcode on the material. This information is then used to update the inventory control system.

Each of these methods has its own advantages and disadvantages. The best method for a particular business will depend on the size of the business, the type of materials used, and the level of control that is desired.

- Workflow for tracking actual direct material costs:

- Identify the materials that will be used in the job.

- Create a job cost sheet for the job.

- Track the actual quantity of materials used on the job.

- Record the actual cost of the materials on the job cost sheet.

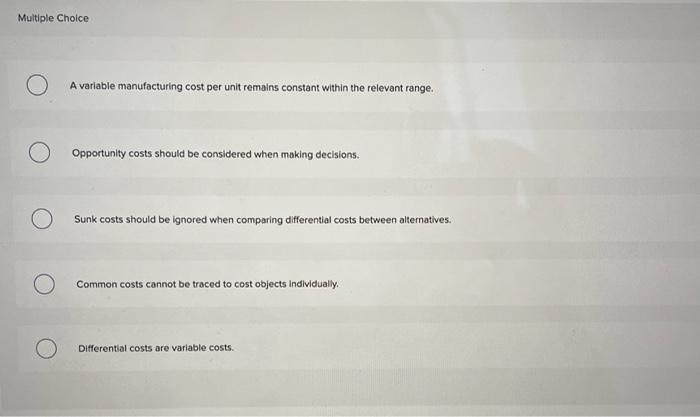

Impact of Actual Direct Material Costs on Job Costing

Actual direct material costs have a significant impact on job costing. The cost of materials is a major factor in determining the total cost of a job. As a result, it is important to accurately track actual direct material costs in order to ensure that jobs are priced correctly.

The relationship between actual direct material costs and job profitability is direct. The higher the actual direct material costs, the lower the job profitability. This is because the cost of materials is a direct expense that reduces the profit margin on a job.

The following formula can be used to calculate the job cost using actual direct material costs:

Job cost = Direct material costs + Direct labor costs + Manufacturing overhead costs

Best Practices for Managing Actual Direct Material Costs

There are several best practices that businesses can follow to manage actual direct material costs. These best practices include:

| Best Practice | Benefits |

|---|---|

| Negotiate favorable pricing with suppliers | Lower material costs |

| Use a just-in-time inventory system | Reduce inventory carrying costs |

| Implement a waste reduction program | Lower material costs |

| Conduct variance analysis | Identify areas where material costs can be reduced |

Variance analysis is a technique that can be used to compare actual direct material costs to budgeted direct material costs. Variance analysis can help businesses to identify areas where they can reduce material costs.

Top FAQs

What are actual direct material costs?

Actual direct material costs represent the actual cost of materials used in the production of goods or services for a specific job or project.

Why is tracking actual direct material costs important?

Tracking actual direct material costs allows businesses to monitor material usage, identify inefficiencies, and ensure accurate job costing for profitability analysis.

How are actual direct material costs recorded on job cost sheets?

Actual direct material costs are recorded on job cost sheets as separate line items, typically including the material description, quantity used, unit cost, and total cost.